This is a response to your man @petedotnu, who asked me for a photo tour of my workshop. It’s a space that is still evolving, so maybe this post will be the first in a series.

I was inspired to take up woodworking six months ago, and then became a little obsessed. My friends have been very patient on our weekly Zoom calls as I bang on about wood and very little else. It’s good of Pete to take an interest, but if you know him you’ll know he’s nice like that, and a practical guy himself, and his general curiosity about everything is why we get on so well.

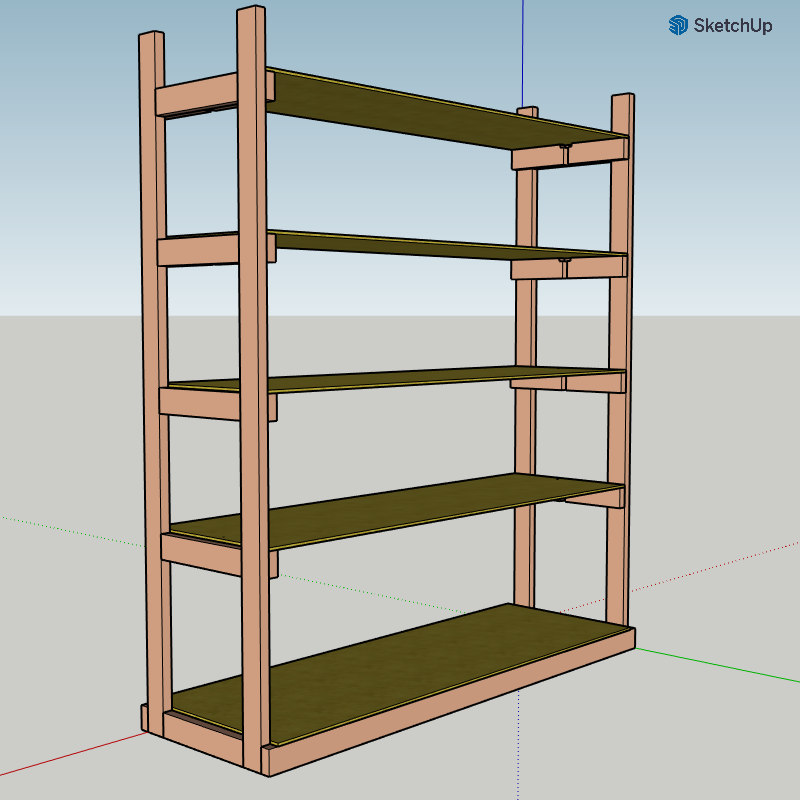

Together with huge stock of wood, my workspace takes up nearly half of our double garage. In the next few weeks I plan to build some shelves down the middle of the garage, floor to ceiling, as far as the up-and-over door allows.

These shelves will hold most of the stuff that is currently stored against the back wall, freeing up that space for more efficient storage of the bikes. The shelves will also help partition my workspace off from the rest of the garage, hopefully limiting my tendency to leave wood and tools in everybody’s way.

I see people on YouTube doing some fantastic precision joinery with table saws and for a while I wanted to emulate that, but I soon realised that’s not going to happen without spending more money than I can justify on a high-end saw. Instead I settled for this Titan, probably the cheapest model on the market that isn’t utter shite, and I got this particular one half-price on ebay. The fence wobbles, and the mitre guide is almost useless, but it’s good enough for rough work. I plan to build a cross-cut sled for this soon, but even without that I can manage some reasonably consistent cuts.

The workbench serves as an outfeed table to the table saw, as it is almost exactly the same height. It’s good and heavy, the top is reasonably flat, and at just £100 for a ready-assembled, six-foot bench it was a good option to get me started. But even though I’m quite tall, I find it a few inches too high for comfort when planing and sawing.

I’m making do without a vice, just using F-clamps to fix my work on or against the edge of the bench. When I’ve built my low roman workbench then this one will be demoted, perhaps to serve as a station for my mitre saw and the drill press I hope to get next year. I’d love to build a traditional English joiner’s bench with a couple of big vices, but that project is a long way off yet.

In front of the bench is this 2.4m oak sleeper. Small, handily sized bits of wood, especially hardwood, are bloody pricey, so it’s better to buy timber in whopping great lumps like this that you can’t lift on your own and that you can spend months tripping over until it’s dry enough to be usable.

Under the bench there is space for six 35-litre Really Useful Boxes. These are good but are usually pretty expensive; I was lucky to get these ones heavily discounted. I have boxes for my circular saw and jigsaw, drill and router bits, planes, clamps, and all of my glues and sanding and finishing gear. I don’t know why the axe and the oak maul are there, I usually keep those in the shed.

I have a couple of crates of other tools, including my lovely new chisels, my antique screw clamp, and one of the mallets I made. This is not a good way to store tools, so I’m working on a design for a dutch tool chest that will hold everything I commonly use, and which I can move around to keep it within reach.

I hung brackets from the joists so I could get some of my stock up and out of the way. Here I have some planed redwood boards that will become my tool chest. On the floor I have a stock of cheap construction timber: treated 2x3s for the garage shelving, untreated 2x4s for my low workbench.

And here is a shot of my bench in use. I clamped a piece across the bench as a planing stop, and I’m using this knotty offcut from a rafter to check the action of my new wooden jointer plane, comparing it with my cheap No.4 smoothing plane. It’s looking good but a bit more fettling is required to get it perfect. I aim to use this plane to joint the edges of the some reclaimed pine scaffolding boards, and glue them edgewise to make a table top that Susan can use on trestles when re-enacting.

Mess is a problem. Mostly my hobby seems to be sweeping up. With this set of hose adapters I can hook up Hetty to the dust ports on almost all of my power tools, and that helps a lot. She’ll catch about 95% of the dust from this mitre saw. On a dry day I can lift my workbench onto dollies and wheel it out onto the drive, and give the space a proper sweep out.